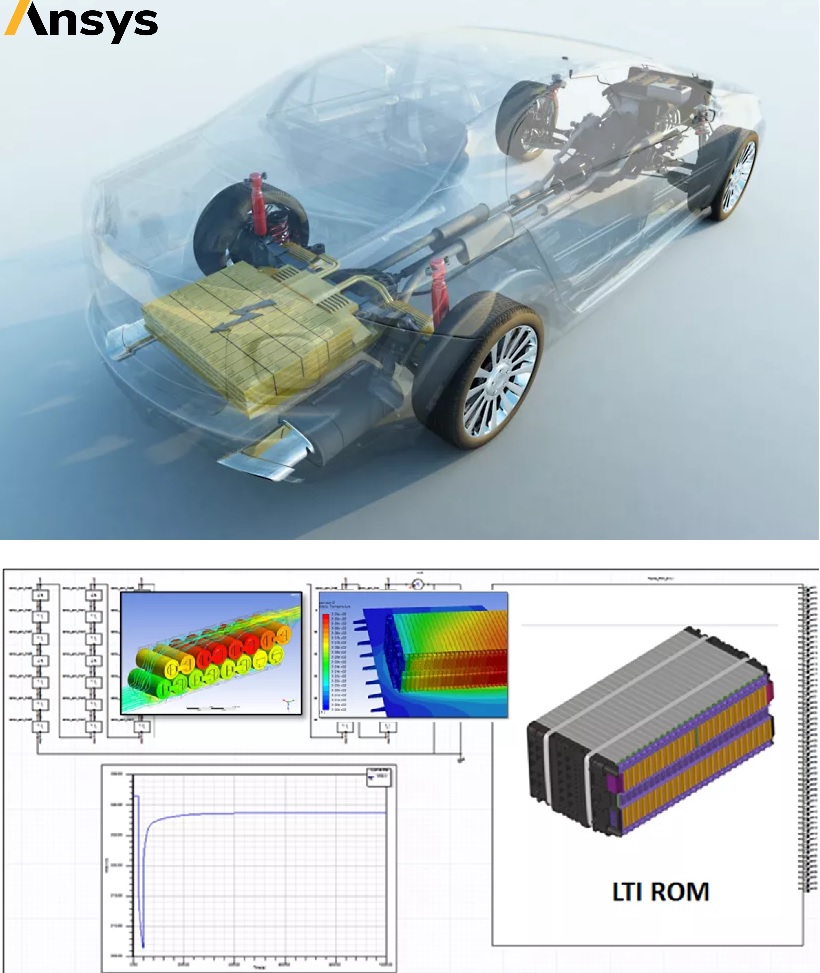

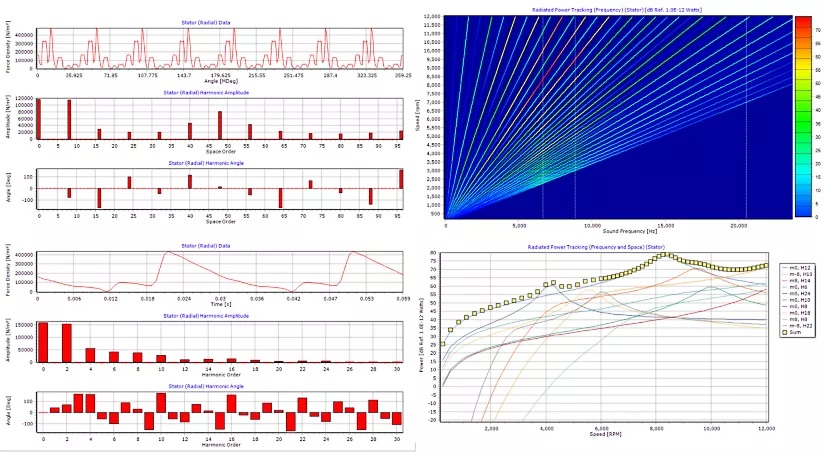

The thermal and acoustic comfort of passengers is a critical design criterion for the air-conditioning and customization of a cabin. Engineers must ensure that the cabin provides a comfortable environment for passengers, which includes maintaining appropriate temperatures, humidity levels, and noise levels.

To achieve this, engineers typically conduct costly and time-consuming test series with specifically built cabin mock-ups to obtain information about the expected passengers' sensation of comfort in the design process. These tests can include measurements of temperature, humidity, and noise levels, as well as subjective evaluations of passenger comfort.

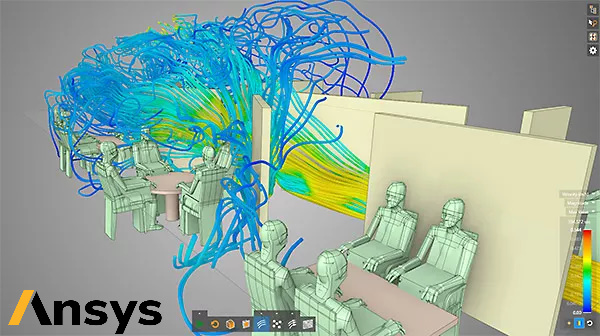

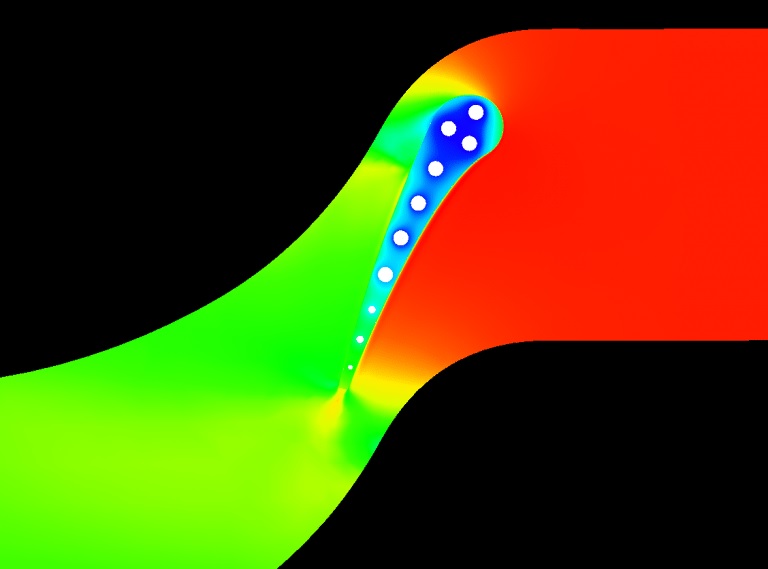

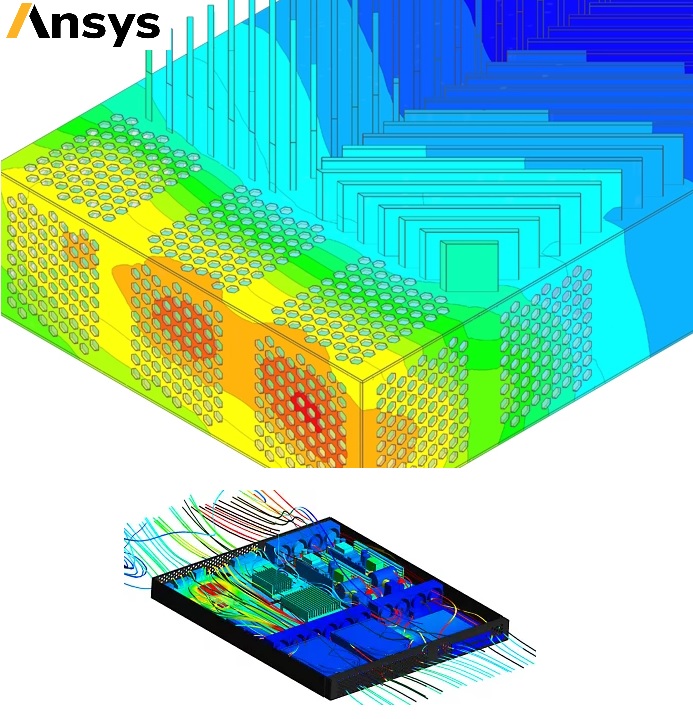

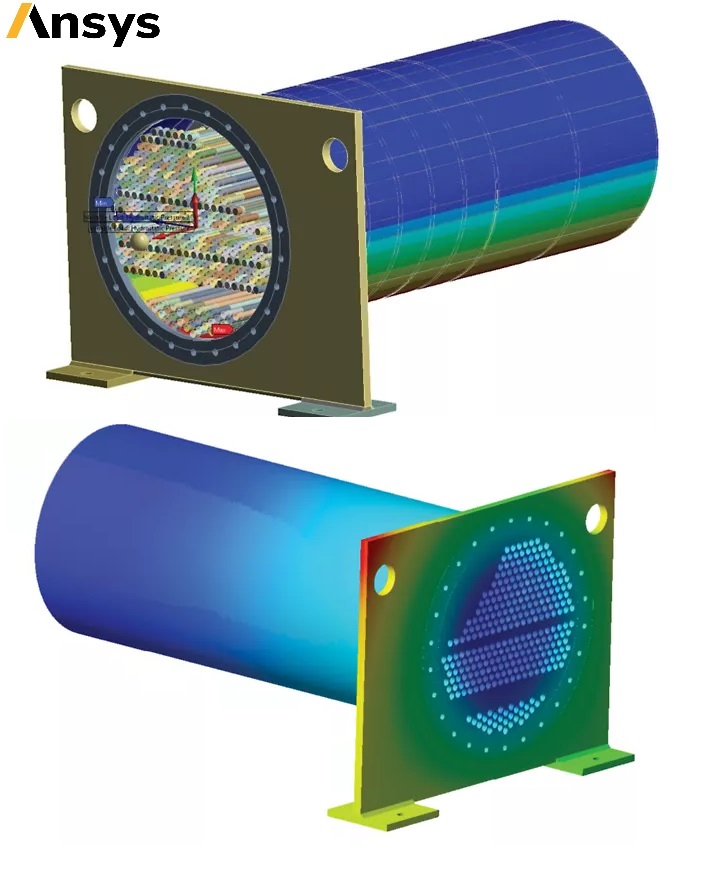

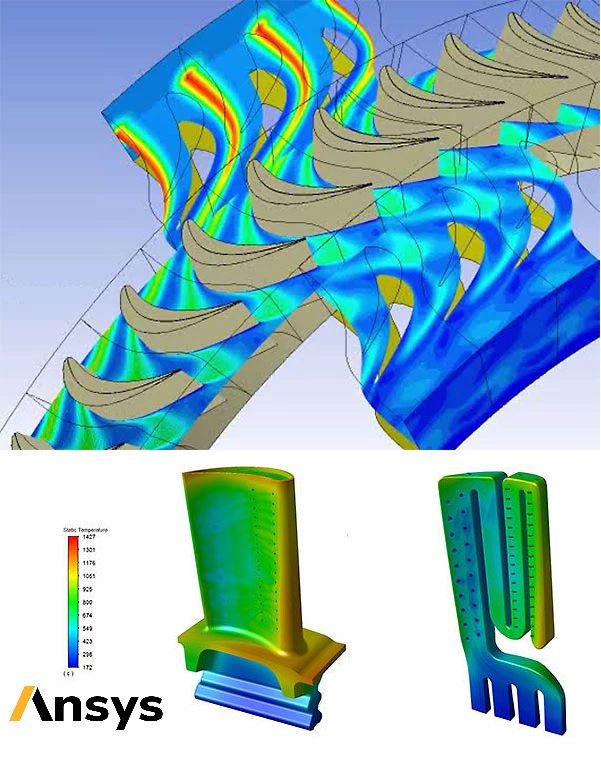

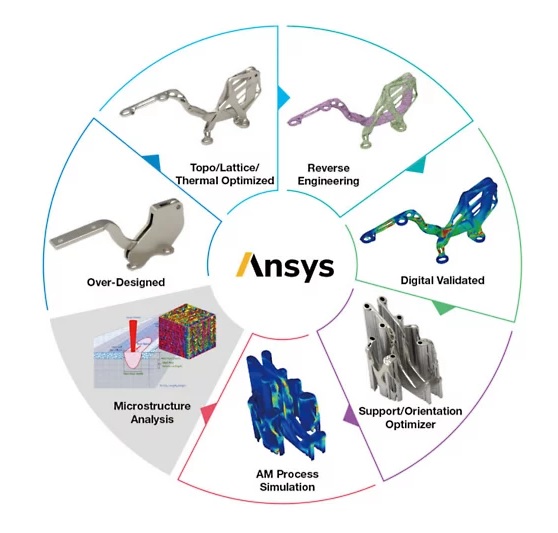

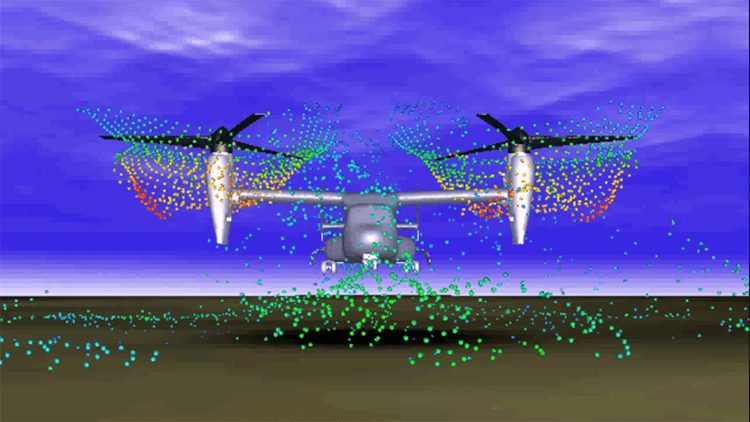

However, to reduce the time and cost associated with physical testing, our engineers use simulation tools such as CFD and FEA to analyze the performance of HVAC components, fans, blowers, and air channels in the cabin. These simulations can provide information on airflow patterns, temperature distribution, and noise levels, allowing engineers to optimize the design of the air-conditioning system and cabin layout for maximum thermal and acoustic comfort.